Moved solutions and added stub for mezzanine connector

This commit is contained in:

parent

8369e7e916

commit

eff3b5cb7d

60

README.md

60

README.md

@ -48,34 +48,6 @@ In order to use more resource efficient hardware this would allow the module boa

|

|||||||

|

|

||||||

The obvious solution would be to use DDR5 SODIMM which has 262pins, but that still feels like using the wrong tool for the job -> Is there a better connecting solution for this usecase?

|

The obvious solution would be to use DDR5 SODIMM which has 262pins, but that still feels like using the wrong tool for the job -> Is there a better connecting solution for this usecase?

|

||||||

|

|

||||||

## Possible solutions

|

|

||||||

|

|

||||||

### Use of Edge Connectors

|

|

||||||

|

|

||||||

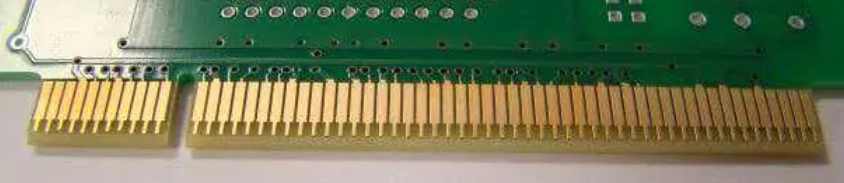

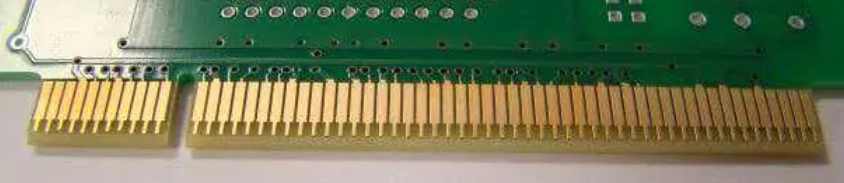

Edge connectors are set of contact points on the edge of the PCB designed to slot into a connector, for example it's often used on PCIe x16 graphics cards:

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

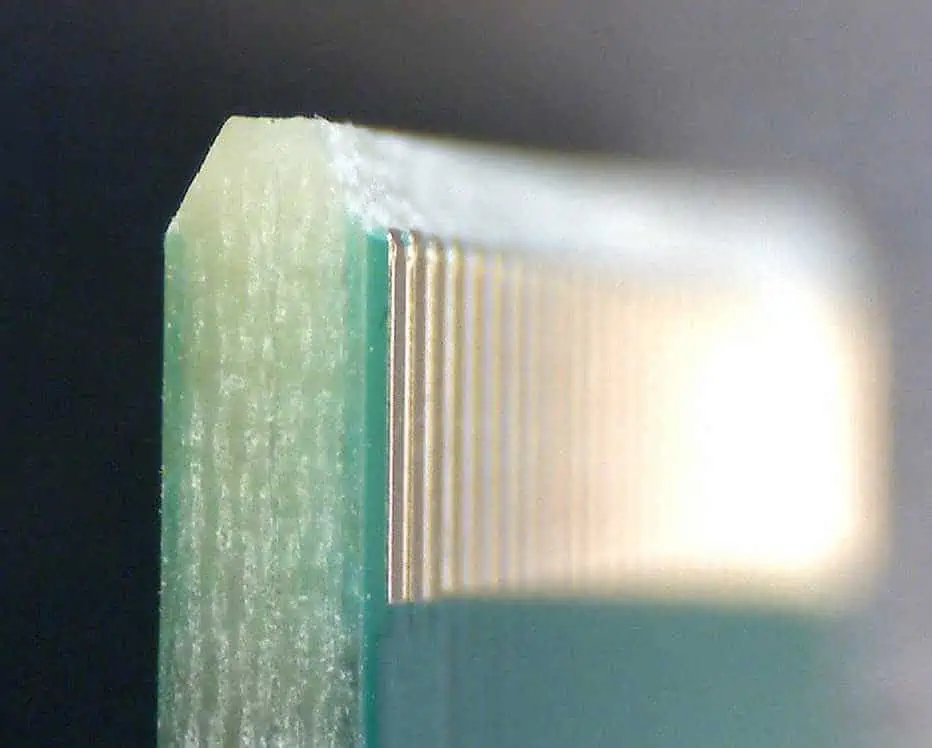

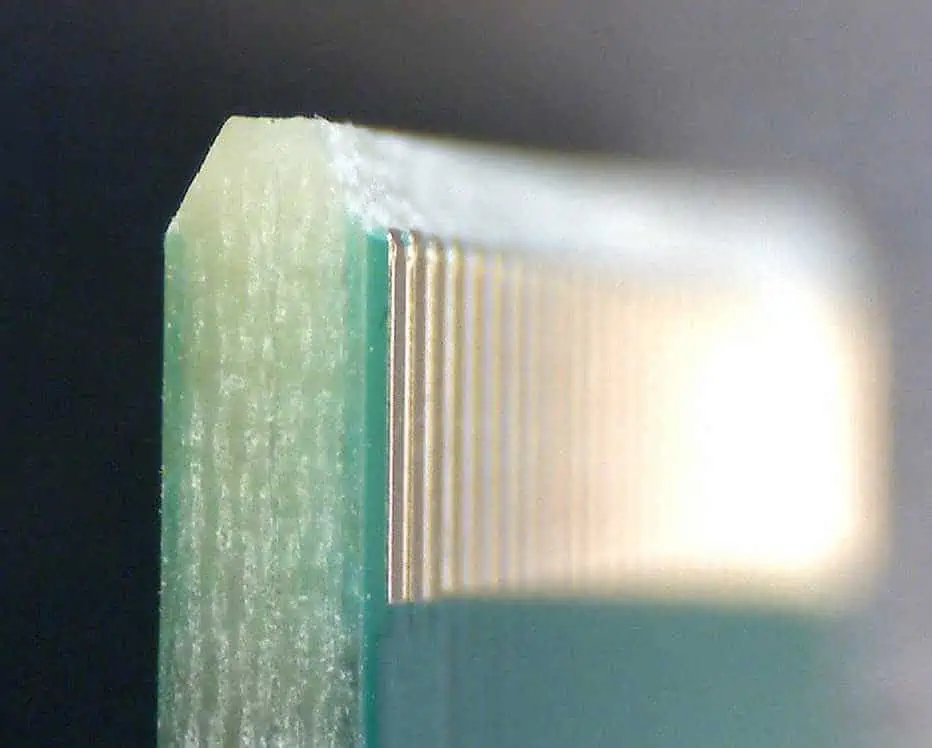

Which has a bevelled edge (minor added cost to fabrication) to fit in the connector

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

One solution could be to standardize these connectors and invent a symbol that can be put over them signaling that they follow this standard.

|

|

||||||

|

|

||||||

Furthermore in practical example this can be adjusted to making Single Board Computers ("SBCs") more functional:

|

|

||||||

|

|

||||||

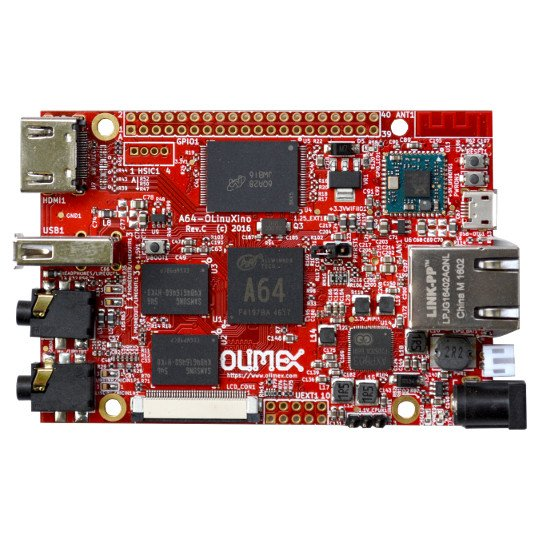

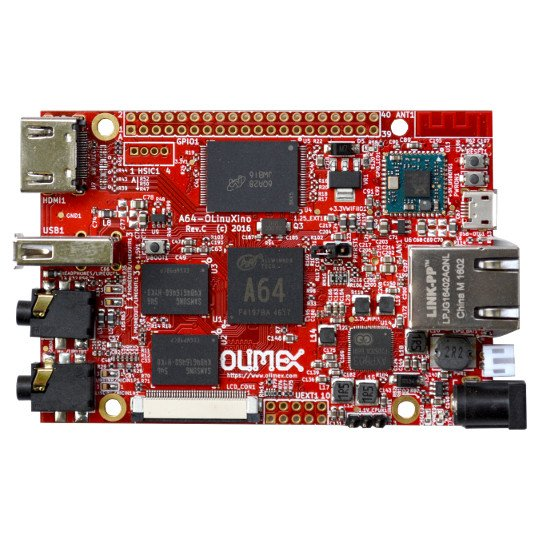

Lets imagine that we have [OLIMEX OlinuXino-A64](https://www.olimex.com/Products/OLinuXino/A64/A64-OLinuXino/open-source-hardware) board as an example:

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

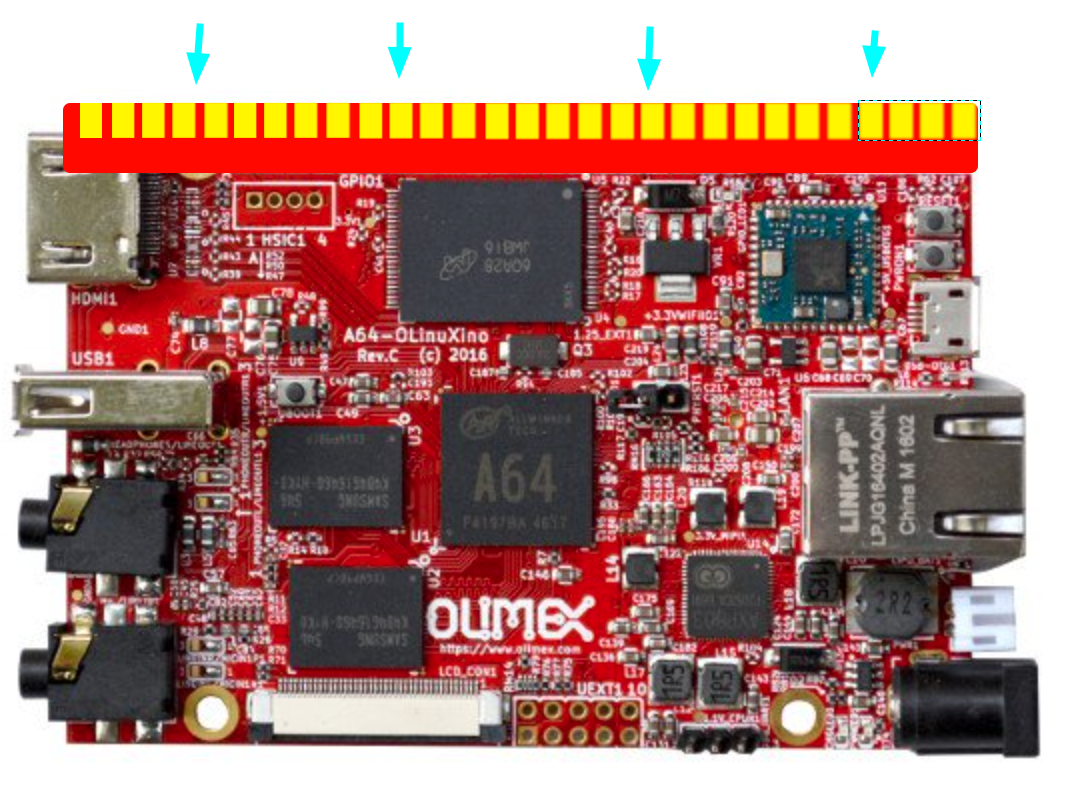

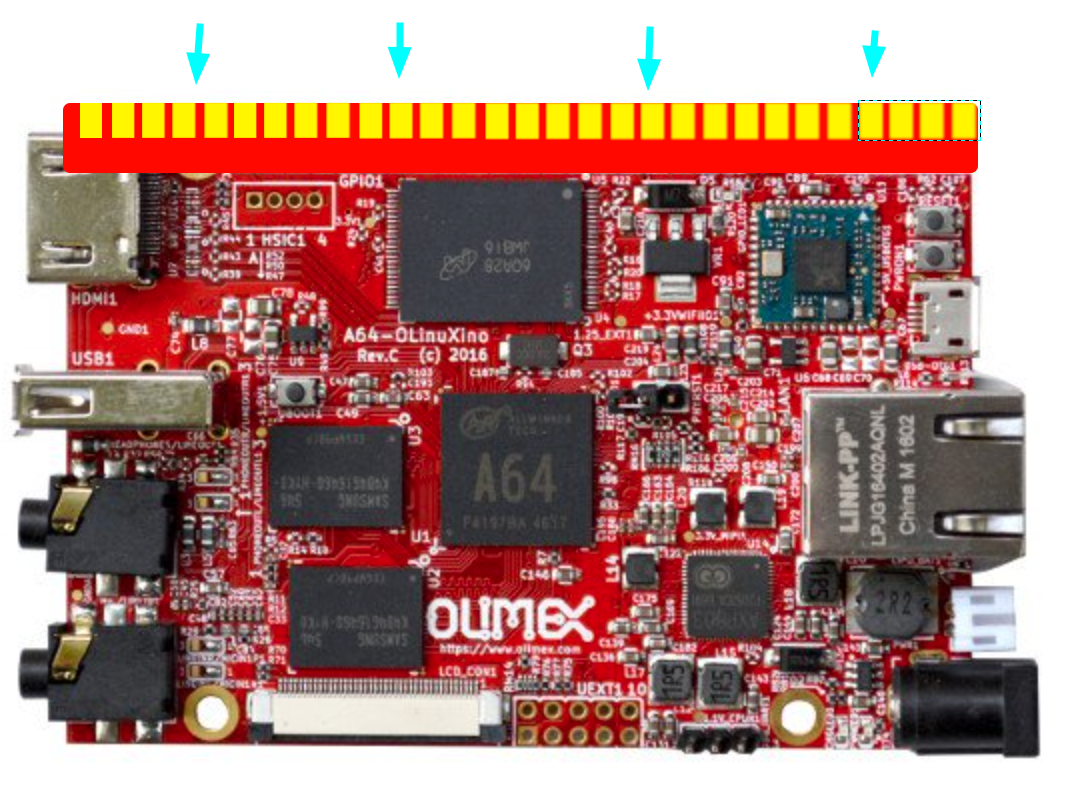

which could have an edge connector some-what painlessly added to it

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

(note that contacts are on both sides of the PCB)

|

|

||||||

|

|

||||||

This would efectivelly enable OSHW manufacturers to adjust their SBCs so that they can be slotted in this solution.

|

|

||||||

|

|

||||||

## Projected cost, fabrication, development and usage of OSHW projects utilizing this standard

|

## Projected cost, fabrication, development and usage of OSHW projects utilizing this standard

|

||||||

|

|

||||||

This standard is a blocker issue for kreyren's (author of this paper) OSHW tablet design for which the abstracted cost and fabrication process is:

|

This standard is a blocker issue for kreyren's (author of this paper) OSHW tablet design for which the abstracted cost and fabrication process is:

|

||||||

@ -137,6 +109,38 @@ Cost and usage unknown

|

|||||||

|

|

||||||

Cost and usage unknown

|

Cost and usage unknown

|

||||||

|

|

||||||

|

## Possible solutions

|

||||||

|

|

||||||

|

### Use of Edge Connectors

|

||||||

|

|

||||||

|

Edge connectors are set of contact points on the edge of the PCB designed to slot into a connector, for example it's often used on PCIe x16 graphics cards:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

Which has a bevelled edge (minor added cost to fabrication) to fit in the connector

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

One solution could be to standardize these connectors and invent a symbol that can be put over them signaling that they follow this standard.

|

||||||

|

|

||||||

|

Furthermore in practical example this can be adjusted to making Single Board Computers ("SBCs") more functional:

|

||||||

|

|

||||||

|

Lets imagine that we have [OLIMEX OlinuXino-A64](https://www.olimex.com/Products/OLinuXino/A64/A64-OLinuXino/open-source-hardware) board as an example:

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

which could have an edge connector some-what painlessly added to it

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

(note that contacts are on both sides of the PCB)

|

||||||

|

|

||||||

|

This would efectivelly enable OSHW manufacturers to adjust their SBCs so that they can be slotted in this solution.

|

||||||

|

|

||||||

|

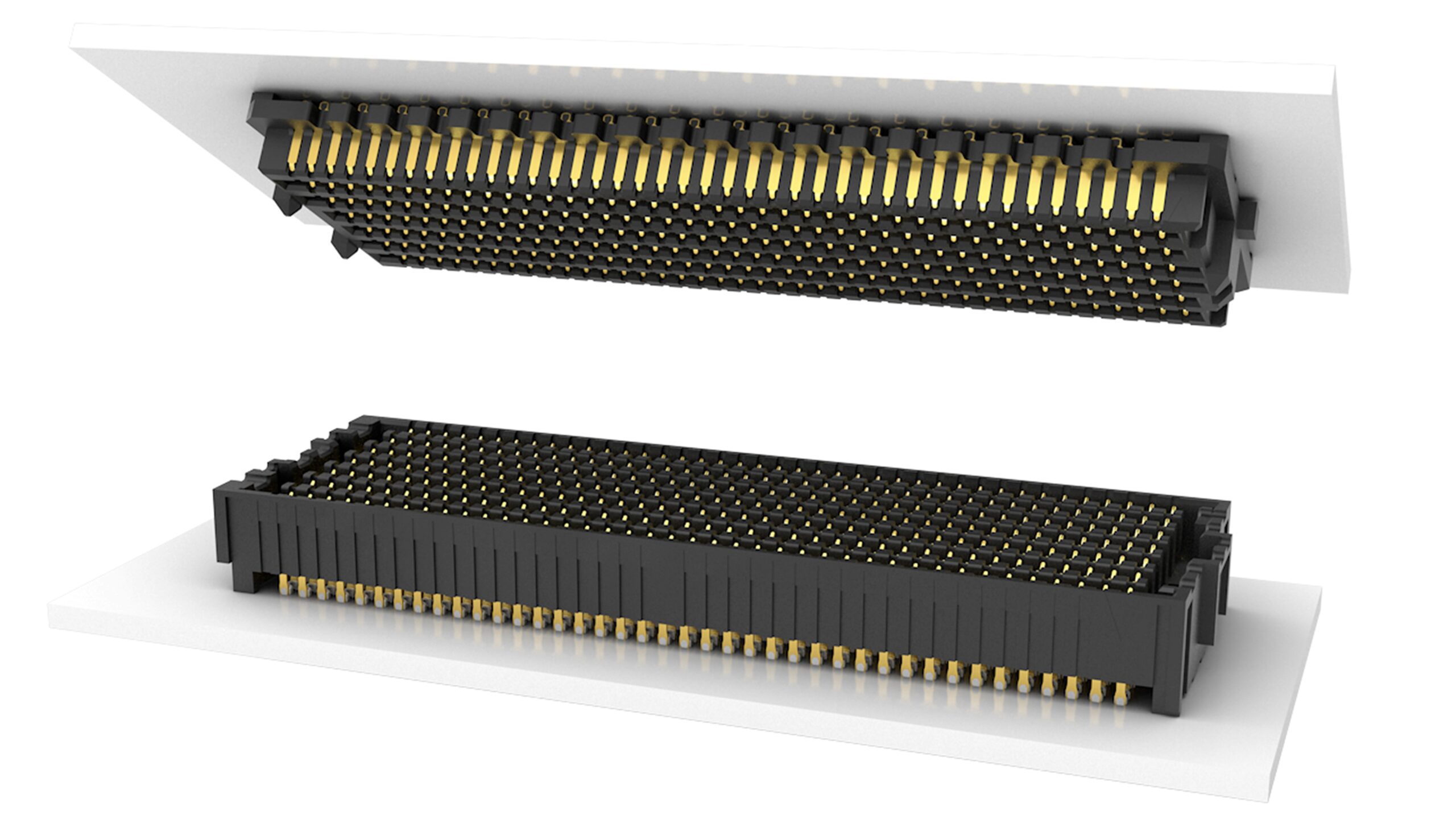

### Mezzanine connector

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

### Additional Notes

|

### Additional Notes

|

||||||

|

|

||||||

Originally discussed in https://git.dotya.ml/kreyren/kreyren/issues/75

|

Originally discussed in https://git.dotya.ml/kreyren/kreyren/issues/75

|

||||||

|

|||||||

Loading…

Reference in New Issue

Block a user