Update 'laser-method.md'

This commit is contained in:

parent

003cfe6adf

commit

331a3ffb90

|

|

@ -1,13 +1,39 @@

|

|||

This file is exporing the options of using laser to make Printed Circuit Boards at FabLab Brno.

|

||||

This file is exporing the options of using laser to make Printed Circuit Boards at FabLab Brno where the projected path of least resistance is to use the laser cutter to cut the PCBs as it's the fastest and most resource efficient method in comparison to engraving traces and then eating away the unwanted copper with an etching solution such as Ferric Chloride (FeCl3) or using CNC which additionally requires special tools namely [drill bit with 0.5mm diameter](https://www.amanatool.com/products/cnc-router-bits/cnc-3d-carving-router-bits/48418-k-m-cnc-2d-and-3d-carving-3-7-deg-tapered-angle-ball-tip-x-50mm-dia-x-25mm-radius-x-19mm-x-3mm-shank-x-75mm-long-x-3-flute-solid-carbide-up-cut-spiral-spektratm-extreme-tool-life-coated-router-bit) and lot of tinkering with CNC with results that potentially cannot compare with laser in terms of precision and width of the cut.

|

||||

|

||||

As of 01.05.2023-EU the makerspace has two industriallaser cutting machines:

|

||||

As of 01.05.2023-EU the makerspace has two industrial laser cutting machines:

|

||||

* Trotec Speedy 300

|

||||

* Trotec Speedy 400

|

||||

|

||||

Both using CO2 Laser.

|

||||

|

||||

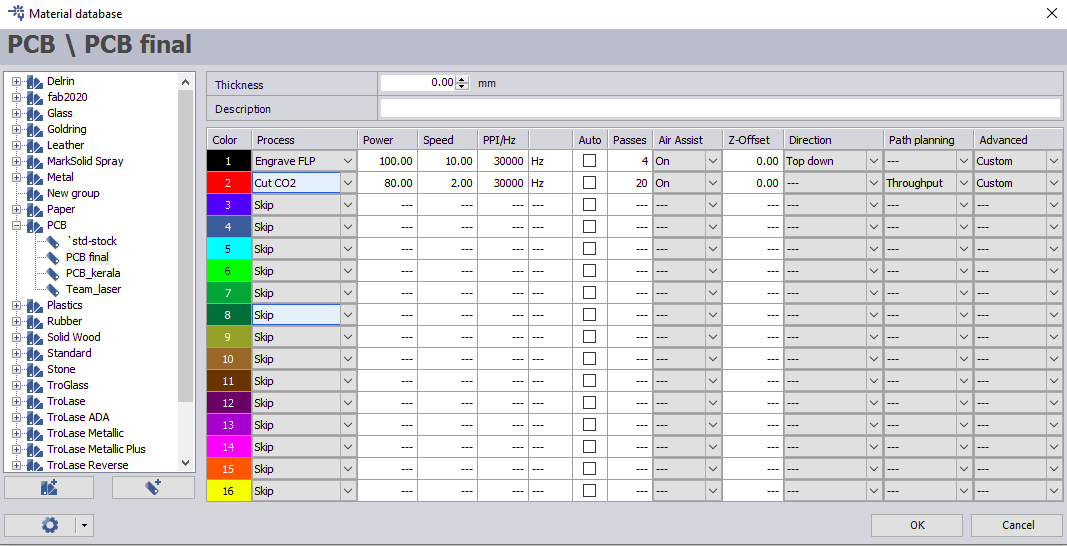

According to the experiments by Saheen Palayi from FabLab Acedemy 2021 the Trotec Speedy 400 with a CO2 laser is able to cut PCBs using the following settings[5]:

|

||||

|

||||

|

||||

The next step should then be to confirming the results.

|

||||

|

||||

In terms of safety the concern over the laser reflecting and damaging the machine was highlighted to me where the Trotec itself clarifies in reference 6 that for the laser to reflect it has to be special super polished metal mirror and reminding that the laser needs to be focused in order to cut where reflection would disperse it's beam rendering it useless.

|

||||

|

||||

Another potential risk highlighted was that cutting such material may release toxic chemicals, but according to the reference 7 such toxicity is not known.

|

||||

|

||||

Another potential risk was fire where reference 5 shows using the same machine without an issue and reference 8 by firefighting website clarifies that:

|

||||

|

||||

> Like most metals, copper is solid and while it has a relatively low melting point for a metal, but it does not ignite at commonly encountered temperatures and is therefore not flammable. [8]

|

||||

|

||||

It does mention the risk of flame if it's set to dust particles which can be seen on reference 9, but such scenario is considered as not relevant for the reasons explained to the use on the laser cutter. Just as a safety measure when performing the test I will have a D class fire extinquisher ready.

|

||||

|

||||

|

||||

|

||||

TODO: Manage the possible risk of reflection and damaging the laser

|

||||

|

||||

### References

|

||||

|

||||

1. fablab academy page on cutting PCBs with a CO2/fibre trotec laser cutter -- https://fabacademy.org/archives/2015/doc/fiber-laser-cutting-pcb.html

|

||||

2. Video of trotec speedy 100 FLEXX engraving and cutting the PCB -- https://www.youtube.com/watch?v=pXH49ZWdGrA

|

||||

2. Video of trotec speedy 100 FLEXX engraving and cutting the PCB -- https://www.youtube.com/watch?v=pXH49ZWdGrA

|

||||

3. Process by berytech fablab using CNC mill -- http://fabacademy.org/2019/labs/berytech/Electronics_Production.html

|

||||

4. Fablab academy page on fabricating electronical products -- http://fabacademy.org/2021/labs/kochi/students/saheem-palayi/assignments/week4.html

|

||||

5. Video of fabricating PCBs on Trotec Speedy 400 using CO2 laser -- https://youtu.be/bl8-EGnb928

|

||||

6. Video by trotec on cutting mirrors -- https://www.youtube.com/watch?v=N93rjDzbDbQ

|

||||

7. Safety data sheet of FR4 boards -- https://docs.rs-online.com/81c4/0900766b8030ec09.pdf

|

||||

8. Firefighter insider reference on flamability of copper -- https://firefighterinsider.com/copper-flammable

|

||||

9. Copper fire test -- https://www.youtube.com/watch?v=dwsexjcROH4

|

||||

10. Safety data sheet on fibreglass -- https://www.gprdirect.com/1/2/f/1/sds-glass-fibre.pdf

|

||||

Loading…

Reference in New Issue